|

|

|

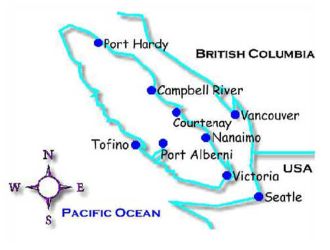

Location

Title

Maps

-

VWVulcan

is in the final phases of a comprehensive search of the

complex titles and rights that is one of the major challenges in development

of a large project such as this.

-

The

link below goes to a page that will be updated regularly with current details

on the state of the title search.

Proximity to Gas Lines

Historic Overview

-

Exploration conducted by BP in the mid 80's in the Nanaimo area.

-

Over 500 cores drilled by coal owners seeking coal; all found gas, but no

measurements were properly taken.

-

180 kilometers of 2D seismic data, some 3D available (BP and Hillsborough

seismic).

-

Coal mines in this region have always had to vent gas to prevent explosions.

-

B.C. Geological Survey has carried out an extensive evaluation of the

Vancouver Island coal resources and gas content analysis.

-

Work was carried out in 1996 in the Tsable River area of the Comox Basin

(six wells drilled, gas content analysis).

-

The Cedar, Yellow Point BP wells encountered Comox coals in Nanaimo Basin at

5,000 feet. One of the wells was plugged and abandoned as result of

excessive gas pressures.

-

Survey results maintained by B.C. Geological Survey in Victoria, B.C. and

managed by Dr. Barry Ryan, Chief BC Coal Geologist.

-

VWV has conducted an extensive geological analysis with the assistance of

Calgary-based geologist Gwyneth Cathyl-Bickford. She has extensive

knowledge and insight of Vancouver Island geology.

CBM Potential

-

Coal rank is bituminous A & B.

-

Geology, rank, and depth all favor CBM presence.

-

Cumulative coal seam thickness is 23 feet.

-

Gas content is 200 to 400 standard cubic feet per ton, most likely higher (PRB

coal’s gas content averages 30 SCF/ton).

-

CBM values reported to date are from desorption tests, not sealed canister

tests, and therefore underestimate the CBM content.

-

Quinsam and Tsable River lands may contain 0.5 TCF to 1.0 TCF of CBM gas,

very possibly more, at average depth of 1,000 feet.

-

Drilling into deeper-lying coals (4,000 to 5,000 feet) may yield additional

CBM production (Yellow Point & Cedar BP wells).

-

Approximately 80 BCF have been identified by VWV from existing Quinsam

Mine core holes.

-

Estimated recoverable reserves 0.5 BCF/well, estimated life in excess of

fifteen years.

Test Phase

-

Ten-well test drilling program to prove gas producing potential of the

Tsable River coals.

-

180 km, 2D-seismic survey completed.

-

Geologic and engineering assessment to determine:

-

Isopachs and extent of major seams

-

Faults and folds

-

Coal bed reservoir (aquifer) water elevations

-

Sorbed CBM values, SCF/ton of coal in place

-

Permeability values of coals

Drilling

-

If the initial test wells confirm production capacity, then: Drill, complete and set compression for 500-600 wells

Time to build-out: five to six years from first production well

Well depths from 800 to 3,000 feet, with an average depth of 1,600 feet

Well spacing: one well per 120 acres

Project development drilling to match gas demand

Drilling will be carried out by conventional water drilling rigs available

on Vancouver Island.

-

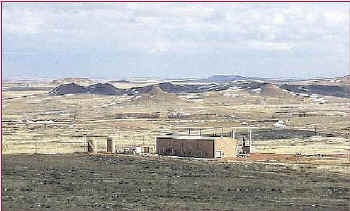

The photograph at right (courtesy of the Bureau of Land Management, Buffalo,

Wyoming) shows a rotary/mud drilling rig. The project will use air drilling,

avoiding the mud pit and tailings pond.

Well Cross-Section

-

After drilling, the casing is cemented in to prevent CBM from escaping from

the well or communicating with overlying aquifers.

-

The tubing, tipped with a submersible electric water pump, is then inserted

to allow the water to flow from the bottom of the hole.

-

CBM exits the well through the annulus formed by the casing and the tubing.

Trenches

A conventional trencher is used to prepare the trenches for gas lines and

water drainage lines.

Wellheads Wellheads

-

The well is fitted out with the required plumbing.

-

The well pod is cleaned up and the wellhead protected by a fiberglass

enclosure. Electrical power to operate the pump is brought in and connected.

-

In cold climates such as Calgary and Northern Wyoming, automatic wellhead

heaters are installed, fueled by the well’s CBM.

Gathering Pods Gathering Pods

-

The gathering lines meet at one of several pods, where the gas is metered

and routed into a header pipe for delivery to the compressors.

-

The pod is shielded by a pre-fabricated enclosure which is color-coordinated

with the surroundings.

-

Gas flow is monitored and recorded.

Gas Compression Gas Compression

-

Gas flowing from the collection pods is delivered to a high-pressure

compression station or stations.

-

Depending on the wellhead pressure, the CBM may be collect by a low-powered

screw compressor and passed on to an intermediate reciprocating compressor.

Production Phase Production Phase

-

On average, each well is anticipated to produce 150MCF of CBM per day.

-

Anticipated peak daily gas production of 80 MMCF cubic feet.

-

Through 2015, all wells expected to produce a total of 0.25 TCF of gas

– approximately a quarter to one half of the projected 0.5-1.0 TCF

recoverable CBM resource.

Water Production Water Production

-

Initially, wells are anticipated to produce at a rate of 9 gallons of water

per minute (compared with a typical PRB well of 12 gallons per minute).

-

Water production is anticipated to decline exponentially. This is a

characteristic found in most CBM wells.

-

Actual water production curves will be refined on the basis of data from the

initial test wells.

-

Water quality is currently being evaluated, and a water disposal method

compatible with the actual water chemistry will be implemented.

Closure Phase Closure Phase

-

Each well, at the end of its economically viable life, will be de-activated

and plugged, and the wellhead area reclaimed.

-

If desired, wells may be reconfigured into water wells for residential or

commercial use.

-

At the end of the project’s life, anticipated to be at least fifteen years,

all infrastructure will be disassembled and removed, and building and well sites

will be reclaimed.

-

Plugging and abandoning procedures will follow generally accepted industry

practices, differing only to accommodate community needs.

|

|

|